Address

No.2 Pei Long Road, Long Yong Kou Village, Rong Gui Street, Shunde District, Foshan City, Guangdong Province.China

No.2 Pei Long Road, Long Yong Kou Village, Rong Gui Street, Shunde District, Foshan City, Guangdong Province.China +86-4008616163 [email protected]

| Item | Standard | Result |

| Plank Size | EN 426 | 182mmx1220mm |

| Total thickness | EN 428 | 4.0mm,5.0mm,6.0mm |

| Thickness of Wear Layer | EN 429 | 0.3mm |

| Weight | EN 430 | 3.6kg/㎡2,5.3kg/m,7.1kg/㎡2 |

| Density | EN 437 | 1800±50kg/m3 |

| Abrasion resistance | EN 13329 | 2800 RPM (0.3mm AC3) |

| EN 660-2 | Group T | |

| Dimensional stability | EN 434 | Shrinkage≤0.2%, shrinkage ≤1.2mm,Warpage≤1.2mm |

| Indentation-residual | EN 433 | ≤0.10mm |

| Light fastness | EN ISO 105 B02 | ≥class 6 |

| Slip-resistance | DIN 51130 | R9 |

| Reaction to Fire | EN 13501-1 | B1 |

| Sound Reduction | DIN 52210 | 5dB |

| Interlaminar Strength | EN 431 | ≥80N |

| Antistatic Property | EN 1081 method C | Pass |

| Resistance to Chemicals | EN 423 | Pass |

| Castor Chair Continuous Use | EN 425 | no effect |

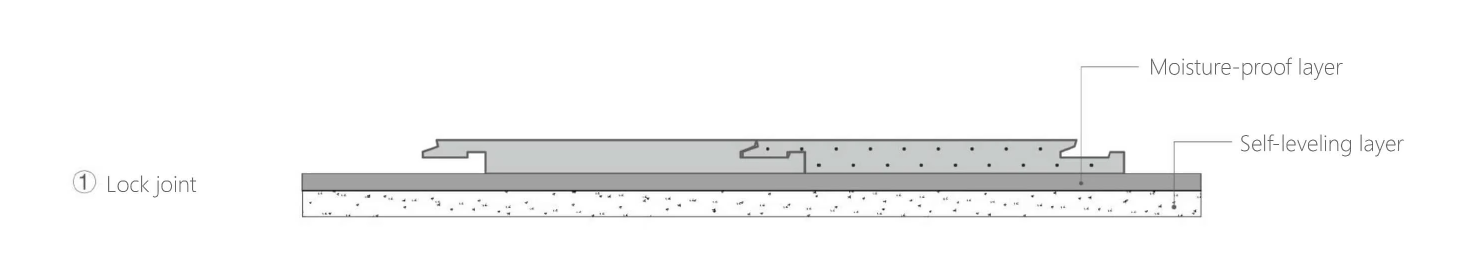

SPC Flooring Structure

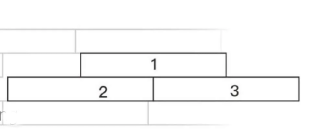

1.Gently lift the 2nd and 3rd boards by hand at an angle of about 60°.

2.Press down on the 1st board with the left hand, simultaneously pulling the 3rd board with the right hand to disengage the locking mechanism.

3.Pay attention to preserving the locking mechanism of the product during disassembly to facilitate future reinstallation.

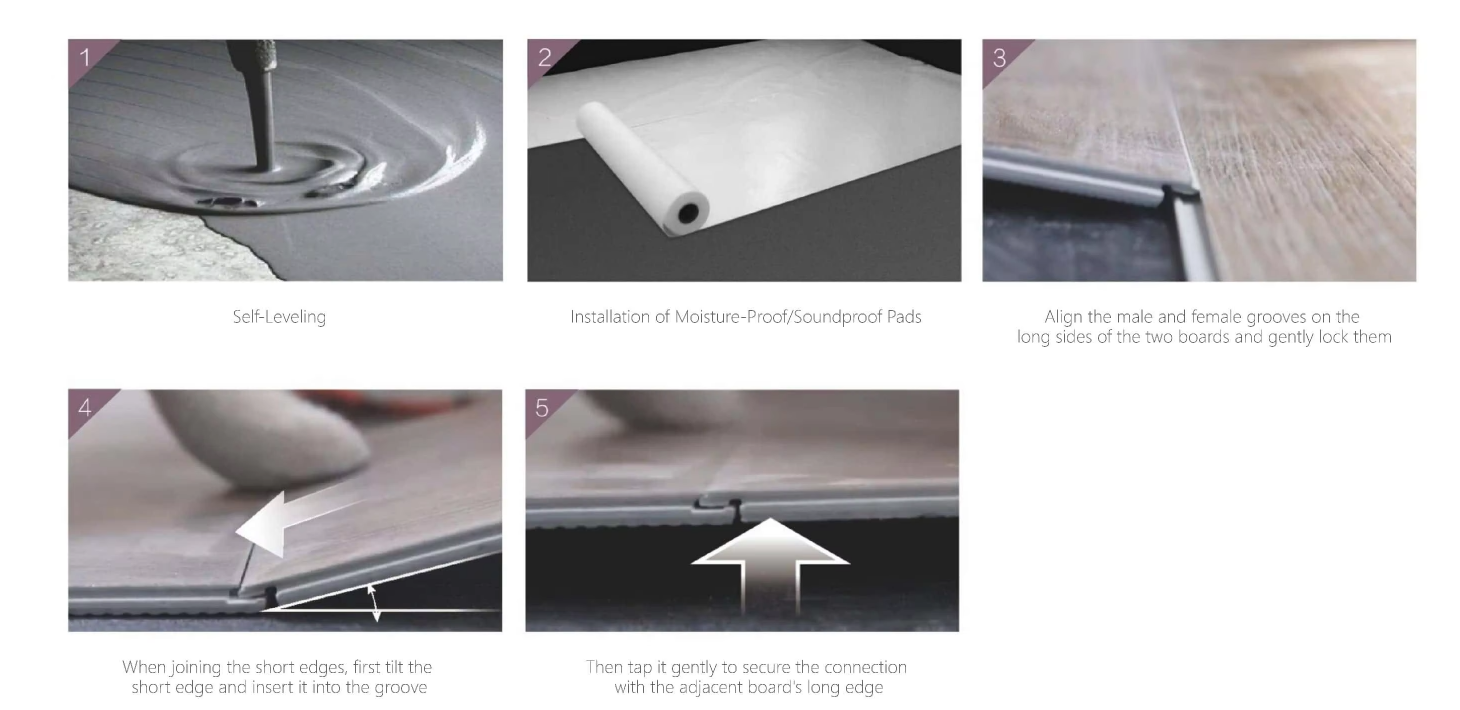

1. Clean the ground thoroughly, ensuring no debris in the construction area.

2. Remove surface sand, oil stains, paint residues, etc., from the base layer.

3. Eliminate protrusions and fill depressions on the ground in the construction area, ensuring overall smoothness and cleanliness.

4. After thoroughly cleaning the floor, apply a layer of interface agent uniformly.

5. Mix self-leveling cement with water according to the manufacturer's requirements, preferably using a graduated cylinder, and stir for 3 to 5 minutes.

6. The floor should be level, and if not, suitable self-leveling should be used. The height difference within a 2m range should be controlled within 2mm.

7. Place the floor in the construction environment 24 hours in advance with the packaging opened. The construction environment and floor surface temperature should be around 20°C; avoid construction below 15°C or above 25°C.

8. Pour the self-leveling cement on the construction surface and use a special scraper to level it. The thickness is generally 2-4 mm according to the requirements of the product. Grout and level.

9. No stepping on is allowed within 10 hours after the completion of self-leveling construction, and avoid heavy impact within 24 hours.

10. The moisture content of the ground should not exceed 3%.

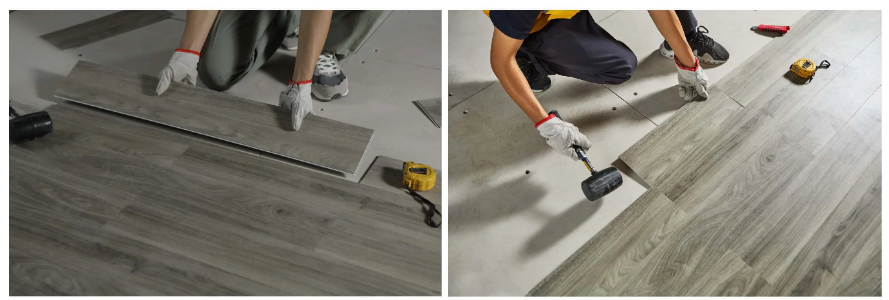

1. Before laying the floor on the ground, a layer of moisture-proof mat (1mm thick) should be laid.

2. The floor uses patented European locking technology, with precise joints. During installation, the groove should be below, and the tongue should be above, naturally embedding at an angle of about 30 degrees, without brutal hammering during construction.

3. If joint damage occurs due to improper construction during the construction process and needs to be removed and re-laid, refer to the installation and disassembly diagrams when disassembling.

4. A gap of at least 8-12mm must be left between the floor and any fixed objects such as walls or pillars.

5. If the room is large, a pressure strip should be used every 8-10 meters, and a gap should be left within the pressure strip.

6. Glass glue should not be directly applied to the floor at the edge of the wall.

7. Damage caused by incorrect construction methods is unrelated to product quality.

| Plank Size | 182mm*1220mm |

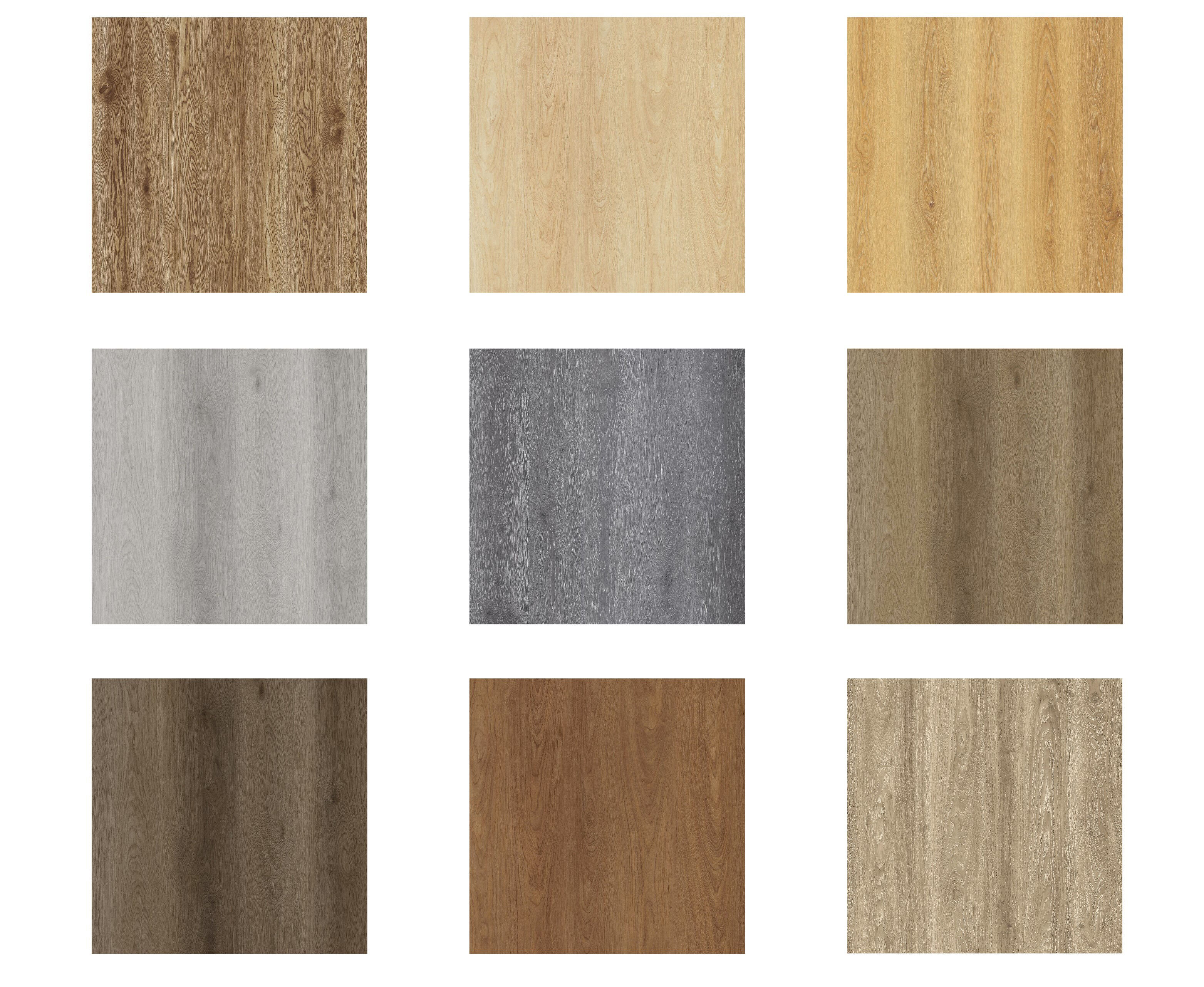

| Color | wood grain, stone grain |

| Application | Apartment |

| Type | Spc Flooring |

| Style | Morden |

The company has a large inventory and can ship quickly.

Cartons、pallets or pack according to customers' requirements.

1. Are you factory or trading company?

We are professional manufacture with our own production line and R&D team.Our factory based in the city of Foshan with 4 plants located in 4 cities across the country, with more than 20 years manufacturing and more than 10 years experiences.

2. What about your lead time?

It depends on the order quantity and the season you place the order. The normal lead time is around 15-25 days. (Samples will be prepared within 5 days)

3. What’s your MOQ? How many color I can choose?

The MOQ is 500sqm, normally one 20’ container with 4 colors from the

4. When can I get the price?

We usually quote within 12 hours after we get your inquiry. If you are very urgent to get the price. Please call us or tell us

in your email so that we will regard your inquiry priority.

5. How do you guarantee the quality of your PVC flooring?

Each step is strictly controlled by the QC team to make sure all our products turn out great. We have SGS test reports and CE certificate.

6. Can you provide the floor accessories?

we provide matching profiles such as skirting, EVA/IXPE sheet etc.

7. Can you produce according to customers' design ?

Sure,We are professional manufacturer ,OEM and ODM are both welcomed.

8. What is your payment terms?

We accept 30% T/T in advance,70% in the period of shipment. Or L/C at sight.

9. Do you charge for the samples ?

According to our company policy ,We provide free samples ,But the freight charges need customers to pay.

10. What are your main products?

SPC flooring, decorative Wall Panels, WPC flooring , Prefab House and other Building Components.

11. Where are your main market?

Our main markets are Europe, Australia, Middle East, Southeast Asia,Russia, South America etc.